01

The Importance of Aluminum Profile Quenching Technology

In recent years, aluminum profiles have been widely used in various fields such as rail transportation, automobiles, and construction, with high requirements for performance and appearance quality. The rapid development of technology has made aluminum profiles an indispensable material in many industries, including but not limited to rail transportation, car bodies, aluminum formwork for buildings, and tablet computers. These end products have extremely high requirements for the performance and appearance quality of aluminum profiles. At the same time, with the popularization of CNC processing technology, the performance of aluminum profiles has been continuously improved, which further highlights the importance of online quenching technology for aluminum profiles. In this context, online quenching needs to meet the dual challenges of rapid cooling and control of deformation.

Product performance and appearance requirements of aluminum profiles

In the current era of rapid technological advancement, the application of aluminum profiles has become increasingly widespread in various industrial fields. From rail transportation, automotive manufacturing to building aluminum templates, and even high-tech tablet computers, all cannot do without the presence of aluminum profiles. These end products not only have extremely strict requirements for the performance of aluminum profiles, but also set very high standards for their appearance quality. Moreover, the widespread popularization of numerical control processing technology has further promoted the continuous improvement of the performance of aluminum profiles. Under such an industry background, the online quenching technology of aluminum profiles becomes particularly crucial, serving as an important means to enhance the performance of aluminum profiles and solve deformation problems.

◇ Online quenching cooling methods

Currently, the commonly used cooling methods in online quenching include air cooling, mist cooling, mixed air-mist cooling, spray cooling, standing wave water cooling, water trough cooling, and liquid nitrogen cooling, among others.

The cooling speed of the air-cooling method is relatively slow, and its energy consumption and usage cost are both relatively high. During the quenching process, the hot air will spread throughout the workshop, causing the ambient temperature to rise. However, the air-cooling method has a relatively small impact on the deformation of the profiles and does not cause the water stains that may occur with water cooling. Therefore, air cooling is suitable for specific alloys, such as 6063, 6060, etc., as well as some thin-walled alloys like 6061, 6005, 6082, etc., including profiles, plates and tubes.

Fog cooling and mixed cooling During the processing, as the fog comes into contact with the profiles and quickly vaporizes, a layer of water vapor barrier is formed, which affects the cooling effect. Therefore, fog cooling is not applicable alone; while the wind-fog mixed cooling combines the advantages of wind cooling and fog cooling. It not only has a faster cooling speed, usually higher than the separate wind cooling or fog cooling, but also has lower energy consumption and less heat diffusion to the workshop. This cooling method is widely used for alloy profiles, plates and tubes with low sensitivity to quenching.

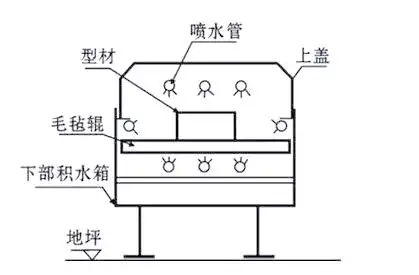

The spray cooling method is extremely fast and is suitable for thick-walled alloy profiles such as 6063 and 6060. The process involves using a high-pressure pump to deliver water to a fan-shaped nozzle, creating a high-pressure water flow that cools the profiles. Although this method has higher energy consumption than traditional water troughs, it can be precisely adjusted according to the different cross-sections of the profiles to reduce deformation.

In the technologies of standing wave water cooling and water channel cooling, standing wave water cooling is suitable for pipes and rods, while water channel cooling is typically used in production environments where no radial directional adjustment is required due to its low energy consumption but poor adjustability.

Liquid nitrogen cooling is achieved by directly spraying onto the outlet of the mold, allowing for rapid cooling. Due to its high cost, it is only adopted in specific circumstances.

02

Key factors in online quenching design

◇ Cooling speed and consistency

Online quenching requires ensuring the cooling speed and consistency to achieve the expected performance. The key to online quenching lies in providing sufficient cooling speed to ensure the stable existence of supersaturated solid solutions and optimize the mechanical properties of the profile during quenching. At the same time, the profile quenching must maintain the consistency of the overall cooling speed to ensure uniform performance and reduce deformation.

◇ Strategies for Different Profiles

During the online quenching process, flexible cooling adjustments need to be made based on different cross-sectional shapes and width-to-height ratios. Considering the differences in profile structure and wall thickness, the cooling intensity should be flexibly adjusted, and it is essential to ensure that the upper, lower, left, and right surfaces of the profiles maintain appropriate distances from the air vents and nozzles. This should be a key focus for the designers.

03

Analysis of Mainline Quenching System

◇ System Suitable for Various Types of Materials

The system suitable for various types of materials combines air cooling, air-fog mixing, and high-pressure water spraying functions. Its design ensures compatibility with irregular shapes, pipes, and plates. By adjusting the parameters of the fan and water pump, the production line can meet the cooling requirements of different alloys and material sections, thus achieving the desired production results.

◇ 2nd and 7th series alloy system

This online quenching system is specifically designed for 2nd and 7th series alloys with high quenching sensitivity. Due to the extremely high quenching sensitivity of these alloys, the system is particularly equipped with both insulation and heating functions. Through the flexible designed heating and cooling areas, it ensures that the processing is completed within the strict quenching transfer time. After quenching, the profiles are transferred to the straightening machine for straightening, thereby ensuring that they acquire stable mechanical properties after extrusion.

The above content provides a comprehensive explanation of the key elements and solutions for the online quenching technology of aluminum profiles.